Most people aren’t aware of just how important nitrogen is to our everyday lives. Nitrogen is a primary gas present alongside oxygen in our atmosphere.

Most people aren’t aware of just how important nitrogen is to our everyday lives. Nitrogen is a primary gas present alongside oxygen in our atmosphere.

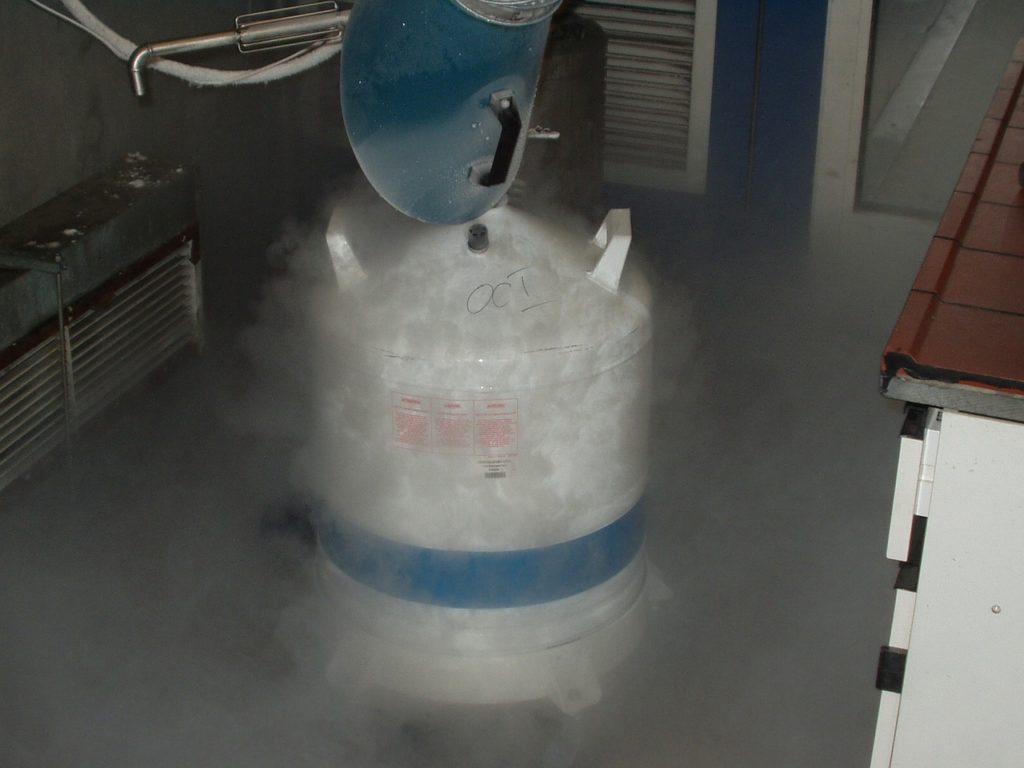

Nitrogen generators work to isolate the nitrogen that is naturally present in the air. Then the generators compress the gas for convenient industrial usage.

Check out a brief look into some of the practical business applications for nitrogen generators, and add a new tidbit of knowledge to your repertoire.

Nitrogen is used in food preservation

When you open a bag of potato chips, there should always be a little pop. You should know that it’s not just regular old air that’s pumped into your chip baggies. Industrial nitrogen generators pump N2 into their baggies to preserve the crisp crunch of the product.

Nitrogen is also used to keep your fruit fresh and crisp for the long journey from the orchard to your mouth. When nitrogen is pumped into the fruits, it displaces the oxygen, so the fruit’s decomposition process is stalled.

Laser-cutting and metal fabrication

Nitrogen is easier on metals like steel and aluminum. In practical application, using N2 for laser cutting means that there’s less heat generated. When less heat is generated, a cooler cut is made. A cooler cut means that professionals are able to make cleaner edges.

In metal fabrication, N2 is an excellent contributor to the annealing process of steel. Annealing is a process used to make steel more malleable for shaping and crafting. Annealing may also be used to repair deformations or cracks in prefabricated metal.

Tank blanketing for explosive prevention

Tank blanketing isn’t the act of placing a blanket on a metal tank. The process is a bit more complicated, as N2 is pumped into a storage tank to offer added protection from the degrading effects of oxygen.

Nitrogen is a gas that has low reactivity with other gases/substances, making it extremely useful for expelling the risk of explosive situations. Oxygen, however, has high reactivity. Pure oxygen is highly flammable.

Grain elevator explosion prevention

Grain silos and elevators make for a perfect storage area. Unfortunately, they make for an extremely ignitable situation.

Adding nitrogen to the mix eliminates the chance of the grain dust being lit up by a random heated spark. The farming industry is especially grateful for the availability of on-site nitrogen generation.

Bottling drinks uses compressed nitrogen

You typically think of CO2 when you think of why your bottle fizzes or pops when you open it, but CO2 isn’t the only way to keep drinks fresh. Nitrogen generation can replace the use of CO2, and it will save production money.